- Open Hours: 24 X 7 online support

- +1 (825) 935-9188 / +86 17717957128

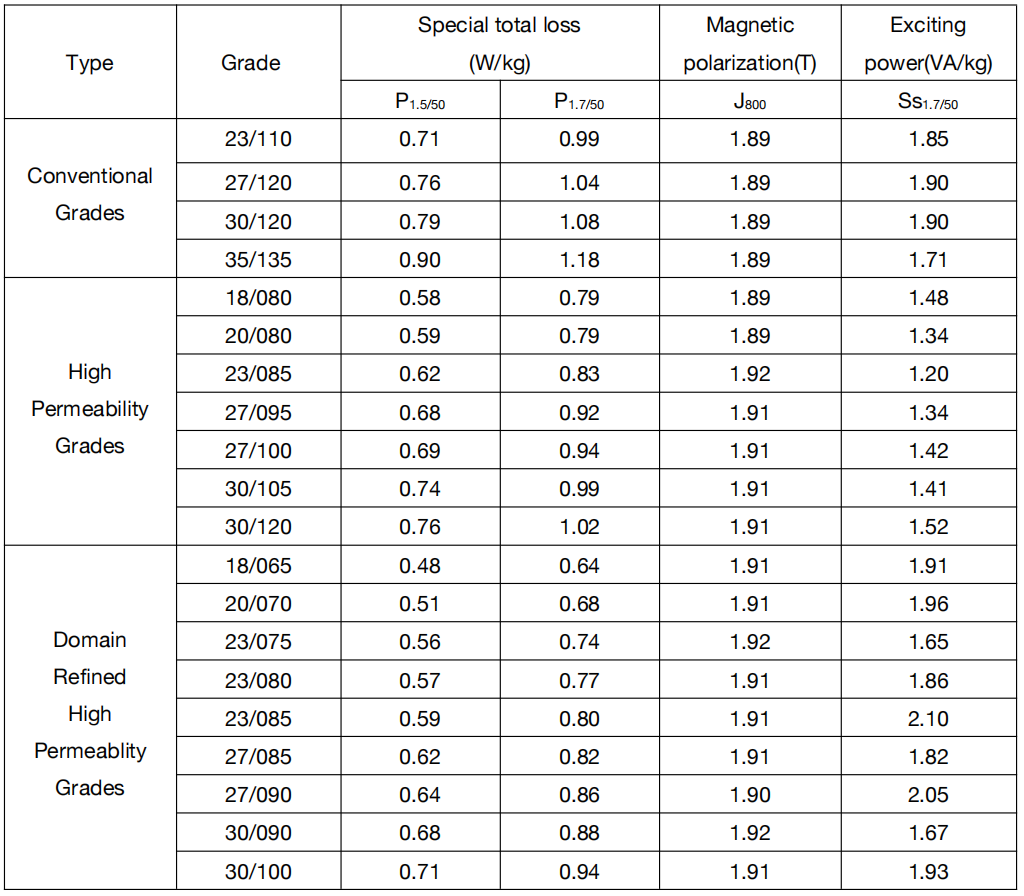

Silicon steel, also known as silicon steel Sheet or Electrical Steel, it is a ferro-silicon soft magnetic alloy steel with very low carbon content, usually containing 0.5% to 4.5% silicon. The addition of silicon can increase the resistivity and maximum permeability of iron to reduce the coercivity, iron loss and magnetic aging.

The difference between oriented silicon steel and non-oriented silicon steel

Non-oriented silicon steel: ferro-silicon alloy with very low carbon content. In the deformed and annealed steel sheet, its grains are distributed randomly. The silicon content of the alloy is 1.5% to 3.0%, or the sum of the silicon and aluminum content is 1.8% to 4.0%. The products are usually cold-rolled plates or strips, which are mainly used to manufacture motors and generators.

| ID | 508mm |

| Nominal Thickness | 0.15mm,0.20mm,0.23mm,0.25mm,0.27mm,0.30mm,0.35mm,0.50mm,0.65mm |

| Annealing Temperature | 820±20ºC |

| Annealing Time | 1.5 to 2.5 Hours |

| The Rate of Heating and Cooling | Rapid Heating or Cooling Should Be Forbidden |

| Annealing Atmosphere | Nitriding and Oxidation Atmosphere Must Be Avoided |

| Nominal Width | 900~1200mm |

| Weight | 2~5t |

Send Email

Send Email +8617717957128

+8617717957128